SP2000 Series

Plataformas de automatización llave en mano o personalizadas.

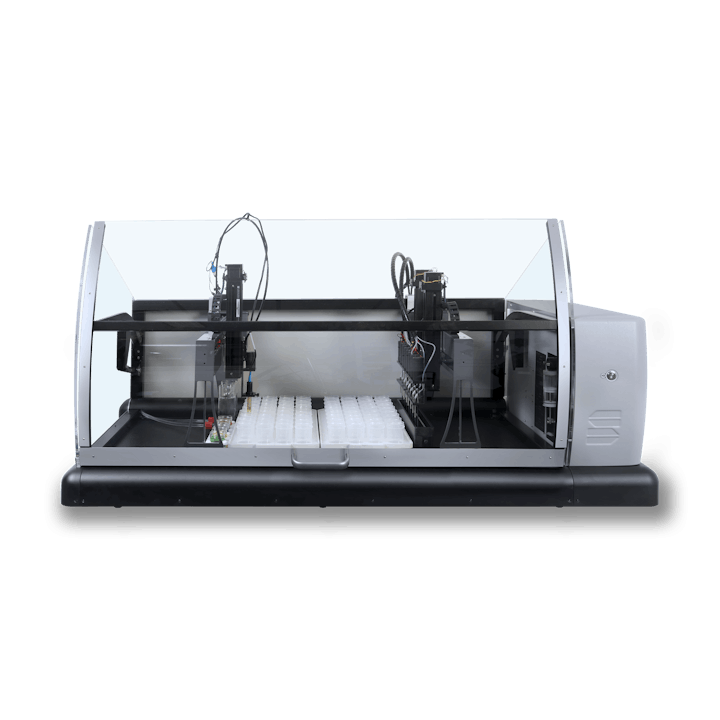

Las sofisticadas plataformas robóticas SP2000 Series de Skalar ofrecen soluciones de automatización dedicadas y flexibles para pruebas analíticas de rutina.

¡La prueba analítica de rutina nunca ha sido tan fácil!

Las soluciones de automatización SP2000 Series están disponibles para una variedad de aplicaciones, incluyendo: DBO, DQO, kit rápidos, pH, conductividad (CE), alcalinidad y otras valoraciones, turbidez, color, aplicaciones de electrodos selectivos de iones (ISE), distribución de tamaño de partículas, pesado automático, filtración de muestras, etc. También son posibles combinaciones de análisis o aplicaciones personalizadas.

Todos los métodos aplicados cumplen con las regulaciones internacionales ISO, EPA, Standard Methods, DIN, etc.

El diseño modular y la automatización flexible y definida por el usuario permiten que los instrumentos satisfagan sus requisitos exactos, lo que aumenta la productividad y la precisión de los resultados, al tiempo que reduce el tiempo

de respuesta de los resultados, los costes por muestra y elimina los errores y la interacción operador/muestra.

La plataforma completa está cubierta por cubiertas frontales y laterales de protección para cumplir con las regulaciones CE aplicables. Los analizadores son controlados por nuestro propio paquete de software RoboticAccess, que incluye archivos de aplicación preestablecidos, programador de análisis, configuración de tabla de muestras definida por el usuario, opciones de impresión y exportación definidas por el usuario a LIMS / Excel y un conjunto extenso de funciones de control de calidad.

Las plataformas SP2000 son actualizables y se pueden modificar de acuerdo con sus necesidades cambiantes, lo que hace que su inversión inicial sea aún más valiosa.

Analizadores robóticos SP2000 Series

Las plataformas SP2000 Series son actualizables y se pueden modificar de acuerdo con sus necesidades cambiantes, lo que hace que su inversión inicial sea aún más valiosa.

Análisis de la Demanda Bioquímica de Oxígeno (DBO)

El análisis de DBO es una de las aplicaciones más comunes en los laboratorios de agua. La prueba se utiliza como indicación de la contaminación orgánica del agua.

El analizador de DBO de Skalar es una de las plataformas más flexibles disponibles hoy en día. Además del diseño moderno y las últimas innovaciones tecnológicas, puede configurarse desde 18 hasta 198 botellas de DBO. El analizador está diseñado para adaptarse a los requisitos exactos de su laboratorio en cuanto al flujo de muestras, nivel de automatización, capacidad de muestras, etc. Los análisis se llevan a cabo con todas las principales regulaciones nacionales e internacionales como EPA 405.1/ISO 5815-1/EN-1899-1/2, Standard Methods 5210 B, DIN 38409, etc. así como con métodos específicos del cliente.

¿Qué se puede automatizar?

- Pipeteo de muestras

- Medición y/o ajuste del pH de la muestra

- Adición de inhibidor de nitrificación (ATU) y/o de semillas

- Adición de agua de dilución

- Homogeneización de muestras

- Medición del valor inicial de oxígeno disuelto (DO1)

- Enjuague de la sonda/agitador entre cada medición

- Tapado/destapado de botellas

- Medición del valor final de oxígeno disuelto (DO2)

- Cálculo de DBO según las regulaciones requeridas

Si se requiere otro análisis como pH, conductividad, alcalinidad, estos se pueden combinar con DBO en el mismo robot.

¿Quieres ver cómo funciona? Haz clic en el botón para ver nuestro vídeo demostrativo.

Análisis de la Demanda Química de Oxígeno (DQO)

El análisis de la demanda química de oxígeno (DQO) se utiliza comúnmente para determinar la cantidad de contaminantes orgánicos presentes en las aguas superficiales y residuales. El valor de DQO es un indicador útil para medir la calidad del agua.

DQO (ISO 15705/EPA 410.4)

La automatización de este método se basa en la misma reacción que el método clásico, pero en lugar de la titulación, se utiliza una detección fotométrica. Todos los pasos de manipulación manual están automatizados. Una ventaja es el uso de tubos pre-preparados, lo que minimiza la manipulación de reactivos tóxicos y peligrosos. Los analizadores se pueden usar con tubos de reacción de DQO disponibles comercialmente o hechos por el usuario y son compatibles con varios fotómetros.

DQO por valoración (ISO 6060)

El analizador se puede configurar con 4-6 racks de muestras intercambiables, cada uno con 20 posiciones. Las muestras pueden permanecer en los mismos viales desde la digestión hasta la valoración, lo que preserva la integridad de la muestra. El analizador está equipado con un valorador, una punta de bureta, una sonda y un agitador. Para expandir el rango sin cambiar la bureta, la plataforma se puede configurar con dos tituladores.

¿Qué se puede automatizar?

- Preparación de muestras

- Homogeneización de muestras

- Valoración de muestras

- Enjuague de la punta de la bureta entre cada medición

- Enjuague del agitador de la bureta entre cada medición

- Cálculo del valor de DQO

Análisis con kits rápidos

Los laboratorios de agua de todo el mundo utilizan pruebas fotométricas listas para usar.

Muchos proveedores ofrecen estos kits para muchos parámetros importantes en el análisis de agua y aguas residuales, como DQO, fosfato total, nitrógeno total, amonio, nitrito, etc. El uso de estos kits es simple y seguro, pero todavía requiere muchos pasos de manipulación manual en el procedimiento de análisis, como la pipeteo de muestra, el (des)enroscado de las tapas de los tubos y la transferencia de tubos. Especialmente cuando la cantidad de muestra aumenta o se deben analizar diferentes parámetros, este proceso puede ser muy tedioso y consumir mucho tiempo. El robot SP2000 puede construirse para acomodar de 24 a 336 tubos en un solo lote. El analizador puede procesar múltiples aplicaciones en paralelo o secuencialmente a nivel de muestra individual.

¿Qué se puede automatizar?

- Pipeteo de muestra

- Tapado (o destapado) de tubo de muestra

- Mezcla de muestra

- Calentamiento/ enfriamiento de muestra

- Adición de reactivos

- Detección fotométrica

El analizador puede ser configurado con un segundo brazo robótico para aumentar la capacidad de muestras utilizando una segunda pinza, una aguja y agitador de muestra o para realizar tareas adicionales. La aplicación del kit rápido se puede combinar con la medición de pH y Conductividad (EC) para procedimientos automáticos de preparación de muestra previos al análisis del kit rápido. Con el valor de EC de la muestra, el software puede seleccionar automáticamente el rango de medición más óptimo para el análisis de DQO de la muestra. La dilución de la muestra y el ajuste de pH de la muestra original antes del análisis también es posible. La comprobación de la muestra antes del análisis puede generar importantes ahorros de costos ya que evita el uso de rangos de medición incorrectos y, por lo tanto, evita el desperdicio de reactivos y consumibles del kit de prueba.

El analizador puede manejar kits rápidos y fotómetros de diferentes proveedores.

¿Quieres ver cómo funciona? Haz clic en el botón para ver nuestro video de demostración.

Análisis de EC / pH / valoraciones / turbidez / color / ISE

Controlar con precisión la calidad del agua potable es muy importante.

El robot SP2000 ofrece a los laboratorios de agua un concepto completo de operación desatendida. Los parámetros típicos para el control de calidad del agua, como el oxígeno disuelto, la alcalinidad, el pH, la conductividad, el color (UV/VIS), incluyendo la filtración, la turbidez, se pueden automatizar completamente.

Las botellas originales de toma de muestras se pueden colocar directamente en el robot, evitando cualquier necesidad de transferencia manual de muestras. Un escáner de códigos de barras integrado lee el código de barras en la botella de toma de muestras. El ID de la muestra, incluidos los parámetros a analizar, se vuelven visibles en la tabla de muestras. El SP2000 inicia automáticamente el análisis en esta muestra de acuerdo con los datos mostrados en la tabla de muestras. Los resultados son directamente visibles después del análisis.

Dependiendo de la aplicación, la calibración de los instrumentos se puede realizar automáticamente para garantizar un rendimiento preciso. Los controles y estándares de control de calidad se pueden colocar entre muestras y las sondas se pueden recalibrar automáticamente.

¿Qué se puede automatizar?

- Escaneo de códigos de barras para comprobar el ID de la muestra y para obtener los parámetros de análisis

- Cerrar y abrir las botellas de muestras

- Filtración de muestra en línea o externa a través de un filtro de banda de papel

- Agitación de muestra

- Enjuague de sonda, agitador, aguja de drenaje, filtros y células de flujo

- Calibración del instrumento

- Cálculo de resultados

Se puede incluir un valorador doble para una mayor capacidad de muestras y se puede integrar un filtro de banda de papel, lo que permite el análisis de muestras de agua cargadas de partículas. El analizador es compatible con numerosos modelos actuales de medidores y sondas de una variedad de fabricantes. Esta configuración es ampliable con flúor, dureza y muchos otros parámetros.

¿Quieres ver cómo funciona? Haz clic en el botón para ver nuestro vídeo demostrativo.

pH en suelos

El valor de pH del suelo nos proporciona información sobre cómo mejorar la calidad del suelo, lo que se traduce en un aumento de la cantidad de cultivos y una reducción de costes.

El analizador SP2000 procesa fácilmente grandes cantidades de muestras de suelo cada día. El sistema agrega el extractante requerido a la muestra, agita, espera un tiempo predefinido y determina automáticamente el pH. Cualquier variable dentro de estas etapas, como el tiempo de pre-agitación y los criterios de estabilización, se pueden adaptar en cualquier momento para acomodar todos los tipos de muestras y normas en una sola ejecución.

¿Qué se puede automatizar?

- Agregar el extractante

- Mezclar la muestra

- Medición de pH

- Calibración y enjuague de la sonda

El analizador tiene una capacidad de hasta 792 contenedores (50 ml). Para lotes extremadamente grandes, el analizador se puede configurar con dos brazos robóticos, cada uno con múltiples configuraciones de electrodos, hasta un total de 12 electrodos, para aumentar la capacidad de muestras. Además del análisis de pH en el suelo, el analizador también se puede extender con la medición simultánea de la Conductividad Eléctrica (CE).

¿Quieres ver cómo funciona? Haz clic en el botón para ver nuestro vídeo demostrativo.

Análisis de la distribución del tamaño de partículas

La clasificación del suelo es importante para el control ambiental y para fines de construcción.

La clasificación del suelo se basa en varios factores, como la absorción, la capacidad de contracción o expansión, la retención de agua y la permeabilidad. La mayoría de estos factores se correlacionan de forma independiente con el tamaño de partícula del suelo. La fracción de arcilla, la fracción más pequeña (0-2 micrones), es indispensable para evaluar la calidad del suelo. La fracción de arcilla se mide según normas como ISO 11277 y permite categorizar el suelo en clases determinadas.

El análisis se realiza en tres pasos:

- Pesar la muestra y separar las fracciones

- Eliminar la materia orgánica y los carbonatos

- Determinar la fracción de arcilla

Skalar ha desarrollado un concepto para automatizar el segundo y tercer paso de este proceso. La automatización de estos pasos es de particular interés porque ahora se pueden llevar a cabo de forma completamente automática, con tiempo y alturas de recogida precisos. La eliminación de materia orgánica y carbonatos se automatiza en el analizador robótico SP50. Con la plataforma SP2000, la determinación de la fracción de arcilla se automatiza.

¿Qué se puede automatizar?

El robot de preparación de muestras SP50

El robot de fracción de arcilla SP2000

- La adición de agua

- El calentamiento de la muestra

- La adición de peróxido de hidrógeno

- La refrigeración de la muestra

- La adición de ácido clorhídrico

- Enjuague de muestra

- Adición de solución de pirofosfato de sodio

- Adición de agua

- Muestra de homogeneización

- Muestra de recogida y transferencia a los platos de evaporación

- Corrección de temperatura para las profundidades de recolección de muestras

- Calefacción de muestras

El SP2000 se puede configurar con 35-105 posiciones para cilindros de sedimentación (1000 ml) y 35-105 posiciones para platos o viales de evaporación. Este procedimiento también se puede realizar de forma desatendida, permitiendo una operación nocturna. Además, también es posible determinar otras fracciones.

Soluciones de preparación de muestras

La automatización de la preparación de la muestra no solo acelera los procedimientos de laboratorio, sino que también ahorra un valioso tiempo operativo y aumenta en gran medida la precisión, la reproducibilidad y la productividad

La plataforma SP2000 es ideal para automatizar los procedimientos de preparación de muestras de manera eficiente y precisa. Las técnicas de preparación de la muestra, como la distribución de muestras, el drenaje, la dilución, la filtración, la adición de reactivos, la preservación, la mezcla, la homogeneización, el ajuste de pH, la muestra original, el calentamiento de la muestra y el enfriamiento se pueden integrar. El robot es compatible con la mayoría de los contenedores de muestra, contenedores de reactivos, bastidores y se puede equipar con múltiples agujas, agitadores y homogenizadores. Varios dispositivos (DE) de captura para viales, tubos y botellas de plástico con tapas de tornillo, botellas de vidrio con tapones y recipientes con tapas magnéticas están disponibles.

Algunos ejemplos de configuración:

El SP2000 puede realizar los pasos de pesaje necesarios para "pérdida de encendido" (LOI). LOI se utiliza para proporcionar una indicación del contenido orgánico de una muestra al monitorear el cambio de peso después de calentarse a alta temperatura (fuera de línea hasta 550 ° C en bastidores a prueba de calor diseñados por Skalar) donde la muestra pierde parte de su contenido al quemarse o volatilizado. Estos bastidores son directamente transferibles desde y hacia el horno y el robot. Las aplicaciones incluyen la determinación del contenido de materia orgánica en materiales como sedimentos, lodo, suelo y desechos, así como aplicaciones industriales para el mismo parámetro en cemento, lima y bauxita.

El robot de pesaje se desarrolla para ayudar en sus requisitos de análisis sólidos (TSS) suspendidos totales (TSS). El análisis TSS es un análisis estándar en la industria de aguas residuales, ya que los resultados del análisis TSS se utilizan para evaluar el rendimiento de los procesos de tratamiento de residuos convencionales y la calidad del agua. Esta aplicación automatiza por completo el proceso de pesaje que consume mucho tiempo, lo que permite a sus analistas centrarse en otras tareas. Además, esta automatización significa que las horas de trabajo convencionales de un laboratorio pueden extenderse enormemente.

En este ejemplo de automatización con nuestra plataforma SP2000, la eliminación, limitar y engarzar las tapas en los viales y también se automatiza la adición de solución de extracción y estándar interno.

Se puede integrar un mecanismo de espaciado lineal en nuestra plataforma de robot SP2000, que es perfecto para una serie de aplicaciones de preparación de muestras. Este mecanismo podría ser un ahorro de tiempo para su laboratorio, al tiempo que provoca uniformidad mediante pipeteo preciso y consistente. Se pueden montar múltiples agujas de recolección en este mecanismo para recoger muestras de botellas de muestra originales y dispensar tinas/viales de análisis de varios tamaños. La capacidad de pasar de contenedores grandes a pequeños en una sola plataforma conduce a una gran reducción en la huella de carbono. Las agujas adicionales para la dilución simultánea de muestras y/o la dosificación de reactivos adicionales necesarios para el análisis se pueden combinar en este mismo mecanismo de espaciado lineal.

Con la implementación del procedimiento de preparación de la muestra para el análisis posterior de la muestra de haluros orgánicos adsorbibles (AOX), el robot se hace cargo de operaciones manuales tediosas y frecuentemente repetitivas como el pipeteo de muestra, dilución, mezcla a velocidades variables, tapado/destapado de botellas de muestra, adición de reactivos peligrosos como ácidos y, por último, pero no menos importante, la dispensación de las muestras diluidas a una velocidad precisa de 3 ml/min a cartuchos dedicados como parte del procedimiento de extracción para un análisis AOX adicional.

El SP2000 ofrece una automatización completa en la adición de solución de extracción, agitación y filtración de muestras de tabaco.

El robot mide primero el valor de EC y PH de una muestra filtrada y centrifugada. Según el valor EC de la muestra, el software robótico puede seleccionar automáticamente el factor de dilución requerido para el análisis de metales posteriores. La muestra se recoge, se diluye y se dispensa en el estante para el análisis de metales. Posteriormente, la muestra no diluida restante se distribuye a diferentes viales para la medición de la medición de carbono orgánico (DOC) disuelto, el análisis de fenol, cianuro y aniones en otros analizadores.

El procedimiento de preparación de la muestra contiene muchos pasos manuales de manejo y puede ser bastante peligroso, debido a la liberación de gases durante el análisis, así como al riesgo potencial de contaminar el laboratorio con mercurio. Por lo tanto, la unidad completa se coloca en una humedad y está equipada con un extractor de "punto" especial para extraer los gases peligrosos en el lugar.

Software

RoboticAccess está diseñado como un programa flexible y multitarea para controlar los analizadores robóticos Skalar. Al analizar las muestras, se procesan los resultados ya obtenidos y se pueden preparar y programar nuevos análisis. Se requieren un código de acceso y una contraseña antes de la operación para evitar la operación no autorizada y la modificación de datos.

Los archivos de aplicación, que contienen las instrucciones para que los analizadores realicen las especificaciones, están preestablecidos en el software por Skalar, de acuerdo con las regulaciones (inter)-

Los análisis se pueden iniciar fácilmente seleccionando la aplicación requerida y simplemente creando una tabla de muestra definida por el usuario arrastrando los bastidores al analizador. Cuando se completa la tabla de muestra y se define la secuencia de análisis, la ejecución se puede iniciar o programar para otra hora de inicio.

Todas las aplicaciones se pueden programar para analizarse. El estado del análisis de ejecución se puede seguir en la pantalla y los resultados se muestran en tiempo real. Durante la ejecución, es posible agregar muestras prioirtarias o excluir muestras de la medición.

Los resultados se pueden imprimir en informes de impresión definidos por el usuario y exportar a un TXT, Excel o LIMS. Los análisis terminados se pueden archivar y respaldar y restaurar más tarde.

Las características de control de calidad integradas aseguran resultados precisos y el cumplimiento total de las regulaciones requeridas. Se pueden analizar muestras de QC y se pueden crear gráficos de control de calidad junto con otra información estadística valiosa. También se pueden incluir protocolos CLP, que permiten acciones automáticas del analizador de robots en sí si se exceden los límites de QC y CLP. Esto garantiza la producción de resultados altamente precisos y un control automático de calidad en el rendimiento del analizador robótico.

Industrias a las que servimos

Claro que hay más que podemos servir, pero aún no los enumeramos a todos.